OPERATIONS

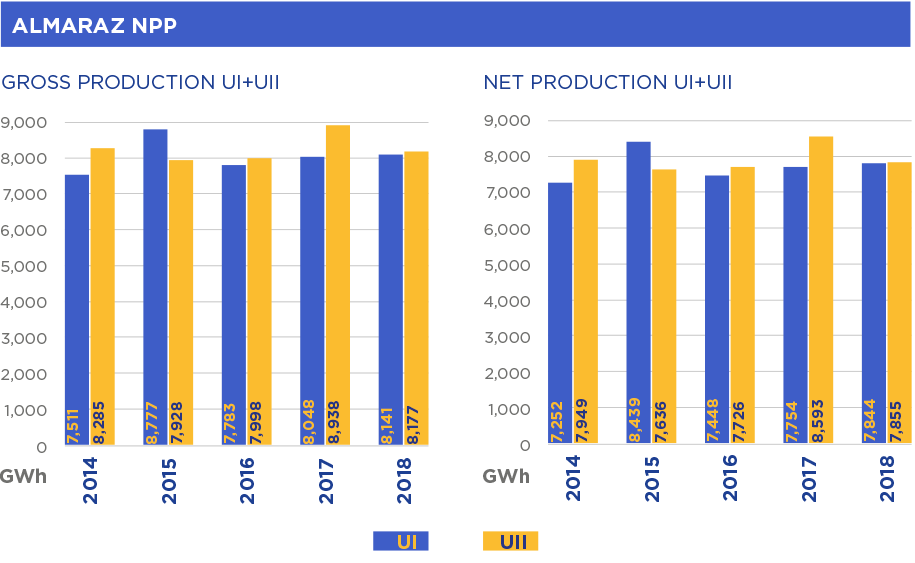

ALMARAZ PLANT

Both Almaraz Nuclear Power Plant units have maintained stable operation in a year in which there have been two refuellings, attaining a joint production of 16,317.6 million kWh, that is 29% of the total generated by the Spanish nuclear plants. Gross electricity production for Unit I was 8,141.1 million kWh, and 8,176.5 million kWh for Unit II. The combined net production of both units was 15,698.8 million kilowatt hours. The cumulative gross electric power production of Almaraz Power Plant was 528,670 million kWh (266,262 at UI and 262,408 at UII).

In May, the Nuclear Safety Council was notified of an event that occurred at Unit II, reporting that when loading emergency diesel generator GD4-4DG for the monthly monitoring test, the fire detection system was activated due to the presence of smoke in the exhaust area of motor B, as a result of oil residues from a small seepage in the connections of the feed pipe to the turbocharger becoming hot.

The Annual Internal Emergency Drill was held in June. During the exercise, a series of circumstances were simulated, such as loss of the steam generator water supply and condensate systems, and the loss of two of the three passive physical barriers with severe damage to the core, which required a Category IV declaration (General Emergency), which includes evacuation of non-essential personnel from the installation.

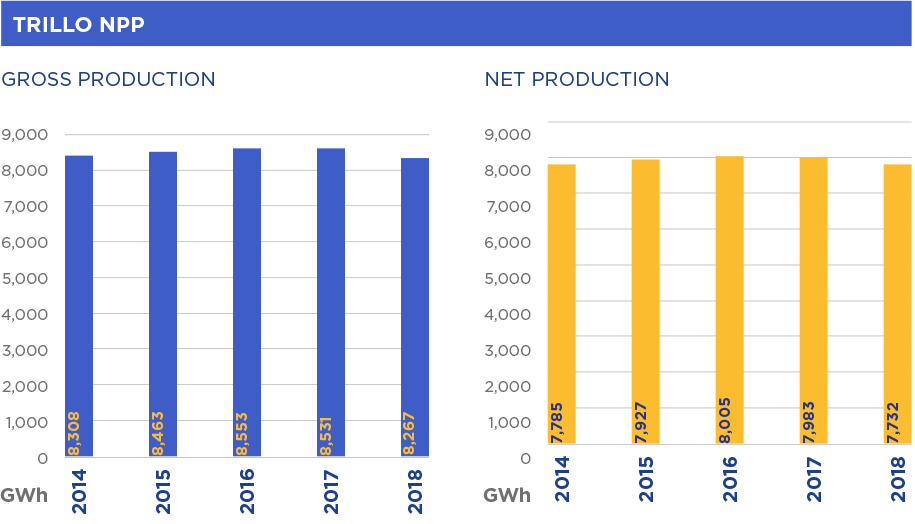

TRILLO PLANT

Trillo Nuclear Power Plant also presented excellent annual operating results: 8,267.2 million kWh of gross electricity generated; 7,732 million kWh of net electric power; it has produced 247,292 million kWh since it started up and has accumulated 11 consecutive years without an automatic reactor shutdown.

As an event notifiable to the NSC, on 9 April, start-up of the GY50 Diesel generator was reported due low voltage in the emergency busbar.

The Annual Internal Emergency Drill was held in October. The scenario proposed initially caused a Category II declaration (Emergency Alert) due to a fire in a transformer and, subsequently, Category IV (General Emergency) with evacuation of non-essential personnel. The Emergency Radiological Monitoring Plan (PVRE) was also activated, as well as the external support organisations required to deal with this emergency situation. This exercise served to verify the readiness of the organisation, the operability of the assigned resources and coordination with the support organisations involved in this type of situation.

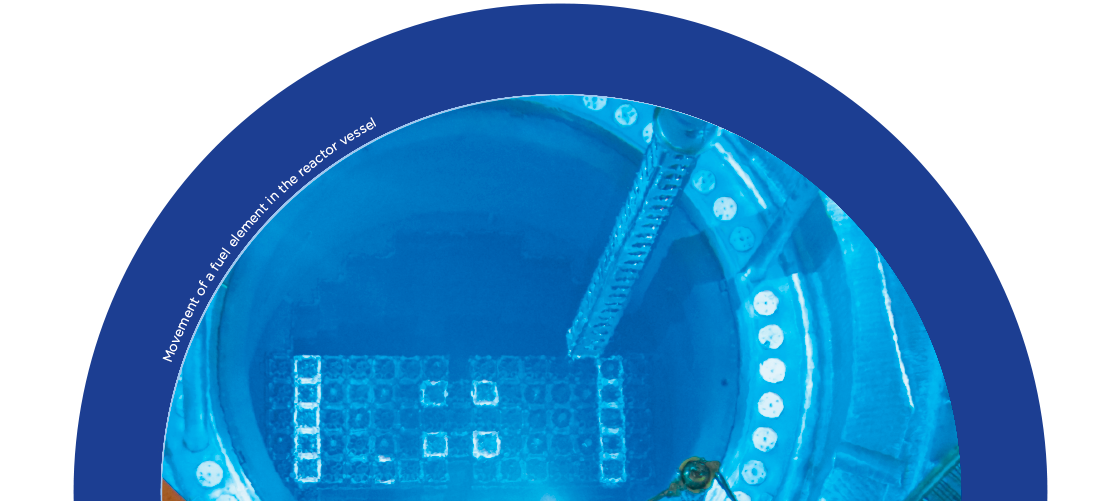

REFUELLING OUTAGES

ALMARAZ PLANT

Both units were refuelled in 2018. In the first half of the year Unit II was refuelled for the 24th time, taking 33 days, from 9 April to 11 May, with implementation of 20 design modifications and execution of over 9,700 overhaul and maintenance tasks on equipment and components, including ultrasonic inspection of the vessel nozzles welds, overhaul of one of the low pressure turbine casings, visual inspection of the penetrations of the vessel cover and bottom, as well as testing the power supply from the Valdecañas hydraulic power plant. The 26th refuelling of Unit I took place during the second half of the year, between 28 October and 2 December, 34 days during which 30 design modifications were implemented and over 9,200 activities were performed, in particular different inspection tasks (vessel nozzles and steam generator tubes), work on the turbogroup and other important tasks such as maintenance of the auxiliary feedwater turbine and the main feedwater pump.

TRILLO PLANT

The twenty-ninth refuelling and general maintenance of the Trillo Plant commenced on 18 May and ended on 26 June. During this refuelling outage, the pins for centring the upper internals of the reactor, the fuel elements and control rods, and the lower bearing in the cooling pump of reactor YD30D001 were all inspected. There was also a mechanised inspection of the reactor pressure vessel and the base material and induced current inspections of 100% of the tubes of the steam generator 20. In addition, pressure tests were performed on the primary circuit, the capacity of the redundancy 2/6 batteries, and checks of the reactor protection system. During this refuelling period, 1/5 redundancy was electrically and mechanically overhauled and the alternator and exciter, and valves of the main steam loop 30 were inspected.

RADIOLOGICAL SAFETY AND PROTECTION

During 2018 the installations operated completely normally, without producing any significant incidents affecting nuclear safety or radiological protection, neither to employees, nor the plant environment.

The results obtained from the measurements performed show the dose rate for professionally exposed personnel was once again well below legal limits. In the case of Almaraz NPP, the staff collective dose totalled 818.10 mSv per person for the combination of the two units, and at the Trillo Plant, the dose totalled 284.48 mSv per person, the lowest collective dose recorded since the plants started operations.

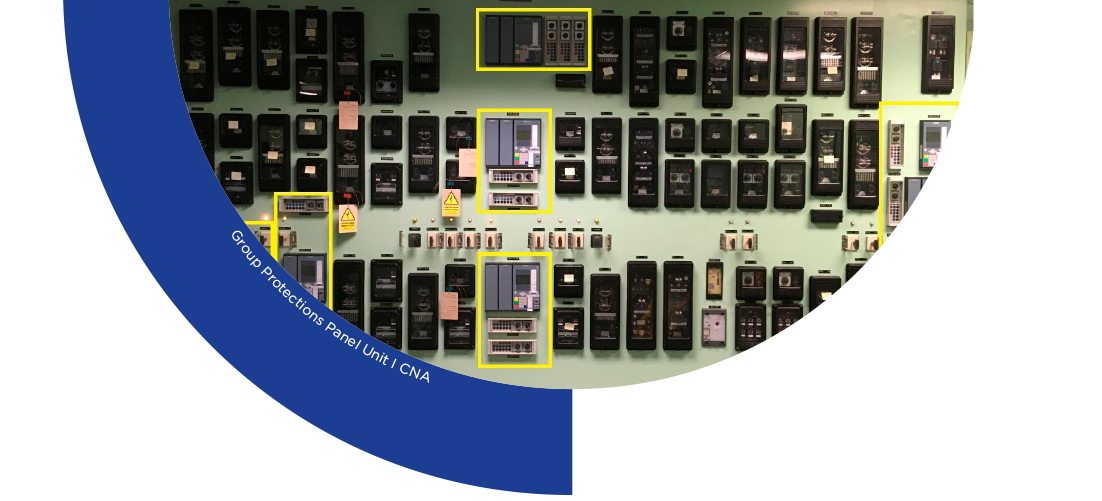

TECHNOLOGICAL UPDATING

Durante During 2018, CNAT continued the investment plan to improve safety as part of the process that has been implemented over recent years, as well as maintaining plant availability by renewing obsolescent equipment. The following actions were performed as part of the renovation plan due to obsolescence:

ALMARAZ NUCLEAR POWER PLANT

• Replacement of power supplies and I&C cards. Foxboro cards have been obtained to increase stock ahead of the termination of production announced by the manufacturer.

• Implementation of the new electric power measurement system (Crossflow) in Unit II saw completion of the renovation and modernisation at both units.

• At the end of 2018, a project was instigated to replace the SMA Actuator with another SMB model. The replacement involves two phases. Implementation of the first phase is planned during R127 and R226 (2020-2021).

• Installation during Unit II refuelling (April 2018) of the new cooling units in the Switch Room on the Electrical Building Terrace, using a new refrigerant gas that does not have adverse effects on the ozone layer.

In addition, during 2018 the Control Room cooling units were placed on the Auxiliary Building terrace for subsequent interconnection with Plant systems. Necessary changes were made to the train busbars during R126 and R224. These new cooling units will be commissioned during the first quarter 2019.

TRILLO NUCLEAR POWER PLANT

• The replacement programme for the METRON switches type Novomax G30 and Otomax P2C continued, using ABB EMAX switches, with a programme covering the replacement of 99 actuators during the 2015-2022 period. This programme includes 660V circuitbreakers and 660V, 380V, 220Vdc and 48 Vdc consumer switches.

• Replacement of S5 programmable controllers, cards and recorders.

• Automation tests on the main steam relief valves.

• The H&B actuator modernisation project commenced with implementation, as planned, of phase 1 during the R430 refuelling in 2018. Initiated in 2018 the design of the modifications for phase 2 that also include replacing the Nuclear Safety actuators and the programme to qualify and dedicate commercial grade actuators was started.

• In the electrical field, replacement of the old GZ40 rotary converter with two new redundant static inverters equipped with a static bypass for automatic power transfer was completed during R430.

SAFETY IMPROVEMENT RELATED ACTIVITIES INCLUDE THE FOLLOWING:

• In 2018, the documentation submitted for the transition to fire protection regulations (NFPA 805) continued to be evaluated by the NSC. Based on work on the part already evaluated, modifications have already been carried out in 2018, representing an improvement in plant safety (re-routed hydrogen lines to the TCV, passive protections in electrical conduits with a significant impact on risk), and further modifications are already planned for implementation in 2019 together with other actions that will take place in the period up to 2021.

• The required modifications to channel and collect oil leaks from the motors of the 3 Reactor Cooling Pumps, OSPS project (Oil Spillage Protection System) have been completed. One tank will be available per pump with sufficient capacity for the entire oil inventory (1,000 litres per pump). Activities associated with IS-30 will be terminated with this implementation.

• Implementation of modifications resulting from IS-30 Rev.2 continued at Trillo NPP during 2018, including improvements to the Emergency Building and which consisted of automating the fixed FM-200 gas fire-fighting systems in the cable rooms and installing automatic detection in various fire zones in this building. In addition, in 2018 the design was finalised for optimising the detection system in Containment that will be implemented during the 2019 refuelling.

• With these modifications and the implementation planned for 2020 to sectorise the roof of the building in fire areas where the safeguard Diesel is located, modifications required to comply with IS-30 Rev.2 issued by the NSC will be finalised. This Project, which has had a major impact on the Plant, will be finally completed within the period 2014-2020.

• Installation of the new Filtered Containment Vent System (SVFC) has been completed at both plants, enabling containment to be vented in a controlled manner at pressures around design pressure following an accident beyond the design bases of the plant, and actions to comply with MINETAD (Ministry of Industry) Conditions are in progress. In accordance with the 2018 plan, the installation of an activity measurement meter in the discharge from the filters of the three filtered containment vent systems (2 at Almaraz NPP and 1 at Trillo NPP) has been completed, and equipment to sample the discharge from each of the filters, the implementation of which is planned in 2019, has been adjudicated.

• Implementation of the modifications required to handle risks resulting from an open phase condition (OPC) in the power transformers from 132 KV (Trillo), 220 kV (Almaraz and Trillo) and 400 kV (Almaraz and Trillo) has been completed at both plants. After implementation and in order to check the correct functioning of the installed protections, as agreed with the NSC, activations have been disabled for one cycle with only one activation alarm available. After one operation cycle and verification of the behaviour, these protections will be enabled in 2019.

• Activities related to the NSC Technical Instruction have continued, following guide NEI 09-10, concerning the prevention and management of gas accumulation in pipelines. At Almaraz NPP, implementation of the planned modifications was completed in 2018,and the designs for phase 1 to be implemented in the 2019-2021 period, and planned activities for phase 2 with a 2021-2022 implementation period were started at Trillo NPP.

With respect to the management and storage of spent fuel and after approval by MINETAD of Rev.4 of the ENSA Safety Study for the new ENUN32P container, authorisation has been received from MINETAD for start-up and fuel loading in both plants. One ENUN 32 P container was loaded at Almaraz NPP and two ENUN 32P containers at Trillo NPP in 2018, and there are plans to continue in 2019 with the loading of ENUN 32P containers at both plants.

QUALITY

Quality is intrinsic to all activities at CNAT and provides the main source of confidence for our owners, the social environment, employees and business partners. Since 1995, CNAT’s commitment to quality has been recognised by the Spanish Association for Standardisation (AENOR) by the award of an official certificate, which certifies compliance of our Quality Management System with the UNE EN ISO 9001 standard for the production of electricity from nuclear sources. In 2018 AENOR carried out an adaptation audit of the new version of the 2015 standard with satisfactory results. In addition, we comply with the reference quality standard in the nuclear sector, UNE 73401 Quality Assurance at nuclear installations, which is the basis of our Quality Assurance Manual, and the requirements are continuously audited by the Nuclear Safety Council (NSC).

Voluntary international evaluations were also requested to determine the degree of excellence of the organisation. These included a WANO Peer Review (World Association of Nuclear Operators), independent evaluation by a group of international experts, which in October 2018 carried out at the Corporate Follow-up of the Peer Review carried out in 2015, with very satisfactory overall results.

Also, there was an OSART mission by the International Atomic Energy Organisation (IAEA) in February 2018 at Almaraz NPP. During OSART missions, a group of experts from the IAEA carry out in-depth reviews of the performance of the nuclear power plant in terms of safety (Operational Safety Review Teams) and to do so they analyse the factors that affect safety management and staff performance. The results were very positive, the IAEA explicitly acknowledging Almaraz’s commitment to long-term safety, as well as notable achievements in recent years, both in its management system and equipment renewal, with safety as a top priority.

Continuous Improvement is part of CNAT’s organisational culture and that is why we manage annually about 5,000 corrective and improvement actions, which originate not only from independent internal evaluations (Quality Assurance audits and inspections and Nuclear Supervision actions), but also from activity and process self-assessments by the units themselves. In addition, trend analyses of low-level incidents are conducted to enable preventive actions to be identified to avoid incidents of greater severity.