ACTIVITY REPORT

ACTIVITY REPORT

OPERATIONS

ALMARAZ PLANT

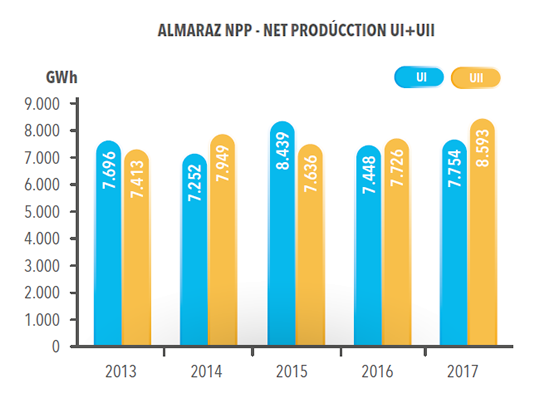

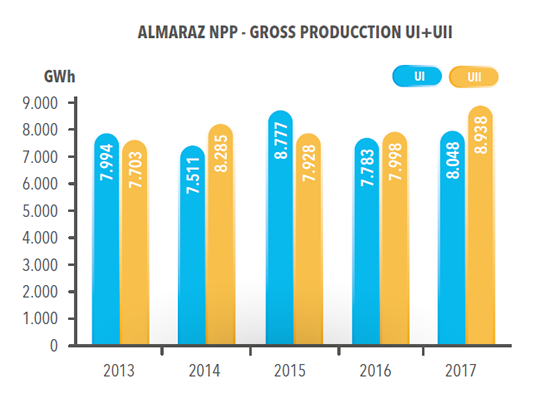

At the end of the year gross production generated by the two units at Almaraz Nuclear Power Plant was 16,986 million kWh, and joint net production was 16,347 million kWh, both data representing another new milestone for the plant as they are the best annual results achieved since the plant started operations. Another milestone in plant operations was the one celebrated on 3 April when an accumulated production of 500,000 million kilowatt-hours was reached. Gross electricity production for Unit I was 8,048 million kWh, and 8,938 million kWh for Unit II.

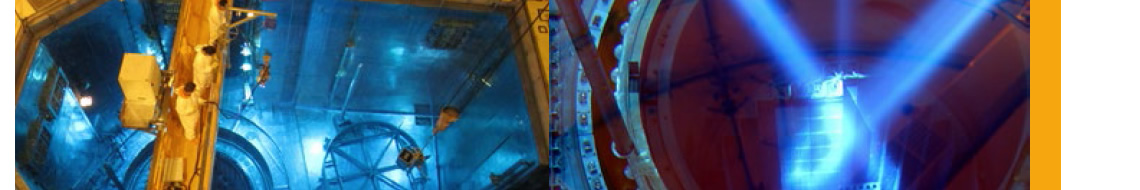

In 2017, the twenty-fifth refuelling and general maintenance outage took place at Unit I. Executed in 32 days, between 26 June and 29 July, more than 9,000 activities were performed with the participation of 1,200 workers in addition to the usual workforce. Significant improvements included installation of the Filtered Containment Vent System, and design modification of the new turbo-pump control for the auxiliary supply water system.

Events reported during the year included a load reduction to 72% nuclear power at Unit I in March due to increased vibrations in a main power water turbine pump, and in April there was an automatic reactor stoppage due to the loss of power supply in one of its cooling pumps. Unit II experienced a scheduled 3-day outage for operability tests on the 4DG Diesel generator.

On 19 October, the Annual Internal Emergency Drill was held, which this year involved declaration of a Category IV emergency (General Emergency). With a scenario that included adverse weather with strong winds and rains, a situation involving the unavailability of the CAT and Control Room communication systems was recreated, for which control of the emergency was transferred to the CAGE (Alternative Emergency Management Centre). Subsequently, additional failures were attributed to various items of equipment that caused complete loss of the functions required to bring the reactor to a hot shut-down. It also included the need to provide care for an injured person, a fire in the safeguards building of Unit 1, and aa request to activate the Military Emergency Unit (UME).

TRILLO PLANT

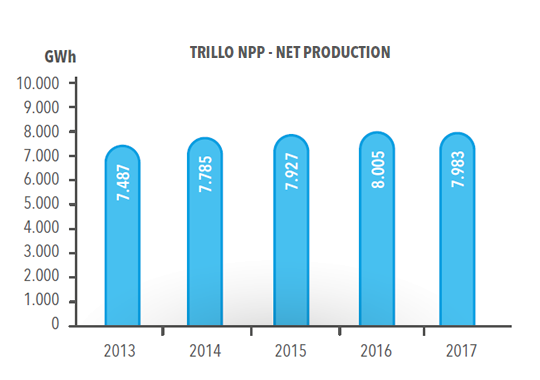

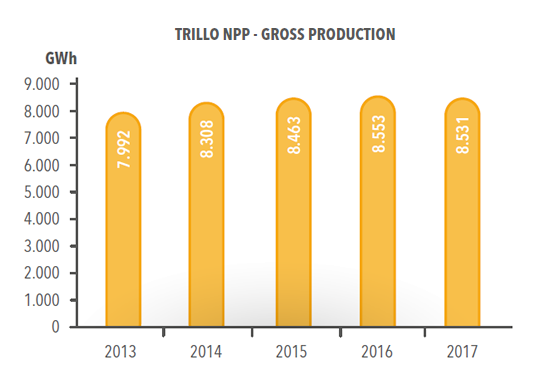

Operation of the Trillo Nuclear Power Plant during 2017 also presented good results with regards to production of generated electric power, 8,531 million kWh, and this was also the year in which the lowest total collective dose was recorded since the plant began its operation, accumulating 10 consecutive years without automatic reactor stoppages.

Improvements made in this financial year include the installation of the Filtered Containment Vent System and the start of design modifications related to the change from DPT containers to the new ENUN 32P containers from ENSA. This is a passive system designed so that, in normal operation as well as in case of abnormal events and postulated accidents, it maintains safety functions: structural integrity, confinement (non-dispersion of radioactive material), heat dispersion capacity (integrity of the fuel), shielding capacity (maintenance of the dose to workers and the public below the established limits) as well as sub-criticality and recoverability of fuel elements.

In June about one hundred civil guards and media belonging to the Air Service, the Rural Security Group (GRS), the Immediate Response Protection Unit (UPRIM), the USECIC (Citizen Security Unit HQ) and Citizen Security Service agents, participated in a drill at the Trillo Nuclear Power Plant, which was also attended by representatives of the Nuclear Safety Council. The Annual Internal Emergency Drill took place on 16 November with an imagined fire at a safeguard diesel, an event that triggered the Internal Emergency Plan in Category II.

ACTIVITY REPORT

ACTIVITY REPORT

REFUELLING OUTAGES

ALMARAZ PLANT

The twenty-fifth refuelling and general maintenance of Unit I took place during the firsthalf of 2017 from 26 June to 29 July.

During this period, activities included fuel unloading, steam generator inspections and fuel loading. Safeguard trains maintenance, penetration maintenance and work on the turbogrupo were carried out in connection with inspection and testing of the alternator and replacement of the exciter, as well as maintenance work on the primary and secondary systems, and implementation of design modifications, including installation of the Filtered Containment Vent System and another related to the new turbo-pump control for the auxiliary feedwater system.

In the 32 days that the refuelling took, more than 9,000 activities were performed and 1,200 additional workers were involved, the majority from Extremadura.

TRILLO PLANT

The twenty-ninth refuelling and general maintenance of the Trillo Plant began on 5 May and ended on 3 June. During the refuelling, approximately 3,700 activities were carried out, including installation of the Filtered Containment Vent System which was particularly important.

Refuelling activities included replacement of fuel elements and inspection of seals in a main pump of the primary circuit, ultrasonic inspection in the main pump housing of the primary circuit, visual inspection of the tubular plate and cleansing of the steam generators, pressure test of the reactor containment, and capacity testing of the DC batteries. The body of the high pressure turbine, main steam pilot valves and the isolation valve was also checked.

1,000 workers from 40 specialised companies joined the usual staff of the Plant to perform the scheduled work. This refuelling resulted in the lowest total collective dose since the plant began operations.

ACTIVITY REPORT

ACTIVITY REPORT

RADIOLOGICAL SAFETY AND PROTECTION

During 2017 the installations operated completely normally, without producing any significant incidents affecting nuclear safety or radiological protection, neither to employees, nor the plant environment.

The results obtained from the measurements performed show the dose rate for professionally exposed personnel was once again well below legal limits. In the case of Almaraz NPP, the staff collective dose totalled 424.42 mSv per person for the combination of the two units, and at the Trillo Plant, the dose totalled 166.63 mSv per person, the lowest collective dose recorded since the plants started operations.

ACTIVITY REPORT

ACTIVITY REPORT

TECHNOLOGICAL UPDATING

During 2017, CNAT continued the investment plan as part of the process that has been implemented over recent years to improve safety, as well as maintaining plant availability by renewing obsolescent equipment.

As part of the renovation plan due to obsolescence, the following actions were covered:

Almaraz Nuclear Power Plant:

- Replacement of power supplies and I&C cards, with the purchase of Foxboro cards to increase stock due to the cessation of manufacturing.

- Modernisation of the auxiliary power water turbo-pump control in Unit I during which the existing control unit was replaced by a new digital one, qualified according to the EPRI dedication guides for digital software, and this renewal was completed and modernised at both units.

- Implementation of the new electric power measurement system (cross flow) in Unit I, which is planned for installation in Unit II during the first quarter of 2018.

- Implementation in Unit I of the new cooling units in the Switch Room that use a new refrigerant gas that does not have adverse effects on the ozone layer.

These new cooling units will be replaced during Unit II refuelling in April 2018. In addition, detailed design of the modifications required to replace the Control Room Cooling units, which also use a new refrigerant gas, has been completed. Deployment of these new Control Room units will begin in 2018, and they are scheduled to begin operations during the first quarter of 2019.

Trillo Nuclear Power Plant:

- Replacement of S5 technology controllers, cards and automated controllers.

- Installation of the vessel new level measurement system during refuelling.

- Launch of the modernisation project for the H&B actuators, on completion of the detailed design of phase 1 to be implemented during the 2018 refuelling.

- In the electrical area, assembly of the new Safeguard rectifiers has been completed, as well as detailed design of the modification in which the GZ40 rotary converter was replaced by two redundant static inverters equipped with a static automatic transfer bypass of the supply, to be implemented during the 2018 refuelling. Manufacture of the new equipment was completed in 2017.

Activities associated with safety improvements include the following:

- In 2017, the assessment of the documentation submitted for the transition to fire protection regulations (NFPA 805) was received from the NSC. The commitments acquired from the NSC to close the evaluation will be resolved during the first half of 2018, and the design of some of the modifications identified in the analyses is already in-hand for implementation in 2018 and 2019.

- Detailed design of the required modifications for channelling and collecting oil leaks from the motors of the 3 Reactor Cooling Pumps, OSPS project (Oil Spillage Protection System) has been completed for both Almaraz NPP units. One tank will be available per pump for the collection, with sufficient capacity for the entire oil inventory (1000 litres per pump). These modifications will be implemented during the Almaraz refuellings during 2018 (April-May U-II and November UI). Activities associated with the IS-30 will be terminated with this implementation.

- Trillo NPP continued this year to implement modifications derived from IS-30, and the improvements corresponding to the expansion of the fire protection detection and extinguishing systems in the main areas of the plant are of note. In addition, the status of the passive protections has been inspected, and the programme to review identified improvements is currently in progress.

- Installation of the new Filtered Containment Vent System has been completed at both plants, enabling containment to be vented in a controlled manner at pressures around the design pressure following an accident beyond the design bases of the plant. All the modifications committed to following the analyses after the Fukushima accident are considered to be completed with this implementation.

- The design modifications required to comply with MINETAD’s conditions for starting-up the Filtered Containment Vent System are currently in progress which requires installation of an activity meter in the filter discharges and a team to take samples in the discharge of each filter. These modifications will be implemented in 2018 and 2019 at both plants.

- Detail design of the modifications required to handle risks resulting from an open phase condition (OPC) in the power transformers from 132 KV (Trillo), 220 kV (Almaraz and Trillo) has been completed at both plants and 400 kV (Almaraz and Trillo). These modifications will be implemented at both plants throughout 2018.

- Activities related to the CSN Technical Instruction have continued, following guide NEI 09-10, concerning the prevention and management of gas accumulation in pipelines. These actions, which affect various systems at both plants, have already begun at Almaraz NPP (2017-2018) and the required preliminary studies are underway at Trillo NPP, with a view to implementing the improvements identified during the period (2019-2021).

In relation to the management and storage of spent fuel, the construction of the Independent Spent Fuel Storage Installation (ISFSI) as well as its interconnection with the Plant was almost completed at Almaraz NPP at the end of 2017, and at Trillo NPP, as a consequence of the container model change, activities required to adapt the facilities and the current ISFSI to the new ENUN 32P model have been completed, and trial runs required prior to container loading are in progress.

We are waiting for approval by MINETAD of Rev.4 of the ENSA Safety Study for the new ENUN32P container, in order to submit the Authorisation request for start-up and fuel loading in both plants.

ACTIVITY REPORT

ACTIVITY REPORT

QUALITY

Quality is intrinsic to all activities at CNAT and is the main source of confidence for our owners, the social environment, employees and business partners. Since 1995, CNAT’s commitment to quality has been recognised by the Spanish Association for Standardisation (AENOR) by granting an official certificate, which certifies compliance of our Quality Management System with the UNE EN ISO 9001 standard for the production of electricity from nuclear sources. In 2017 AENOR performed a follow-up audit to maintain certification of our Quality System and found it to be satisfactory.

Voluntary international evaluations were also requested to determine the degree of excellence of the organisation. These include the WANO Peer Review, independent evaluation by a group of international experts, who in January 2017 carried out a Follow-up at the Almaraz Nuclear Power Plant, and in October, a Peer Review at the Trillo Nuclear Power Plant, in both cases satisfactory overall results were obtained. In addition, WANO Technical Support Missions (TSM) were requested, to evaluate specific aspects with reference to industry best practices, such as in 2017 the Factory Supervision TSM, the Indicator TSM and the Independent Nuclear Supervision TSM, all of them corporate.

Continuous Improvement is part of CNAT’s organisational culture and that is why we manage annually about 5,000 corrective and improvement actions, which originate not only from independent internal evaluations (Quality Assurance audits and inspections), but also from activity and process self-assessments by the units themselves. In addition, trend analyses of low level incidents are conducted to enable preventive actions to be identified to avoid incidents of greater severity.