ALMARAZ PLANT

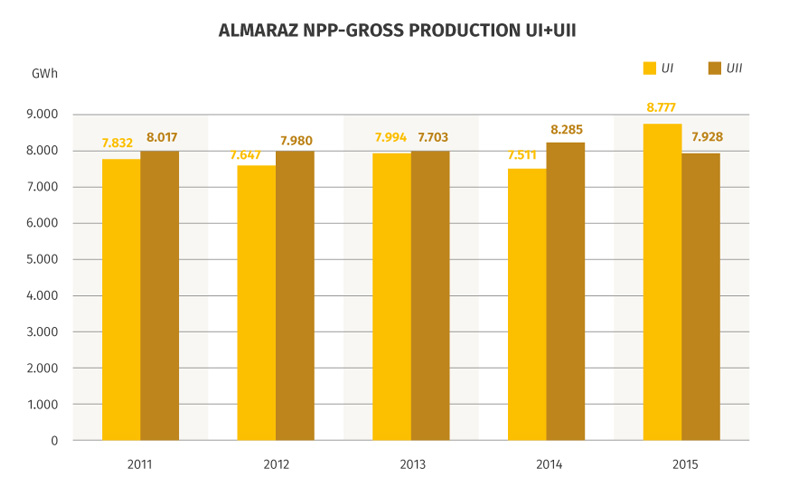

In 2015 Almaraz Nuclear Power Plant achieved a new milestone of combined gross electricity production at its two units, surpassing the previous highest annual production record achieved in 2005 (16,359,973 MWh).

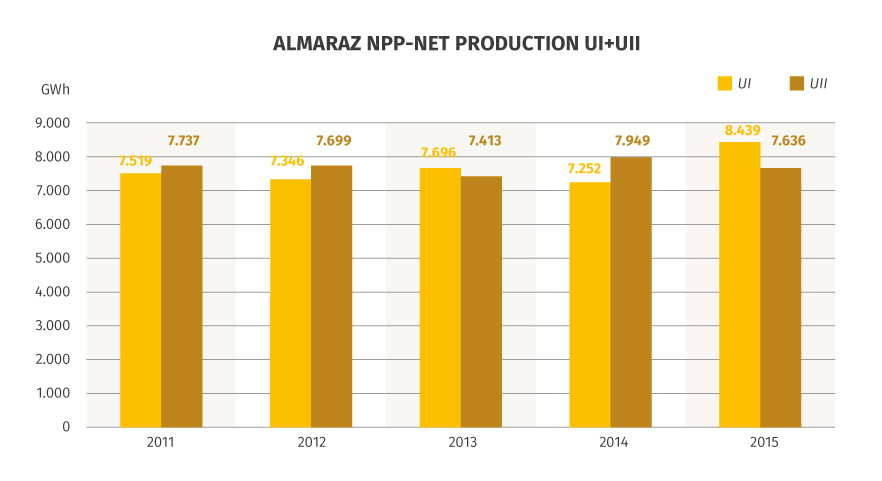

The gross electricity production for Unit I was 8,777,462 MWh, and 7,927,667 MWh for Unit II. In terms of net production, Unit I generated 8,438,616 MWh. and Unit II 7,635,929 MWh.

Unit I has maintained stable operation during the year, with power variations implemented in March (110 MWe) by chemical conditioning of the steam generators, and during April and May (64% and 70% respectively) for repair work on two feedwater turbopumps. A scheduled 5 days outage was scheduled in October to replace the pressurizer safety valve, and in late November a power reduction up to 10% was implemented to repair loss of steam through the MSR-A superheater.

Unit II experienced a 39 days refuelling outage, from 1 June to 11 July. In addition to this outage, a 3 days outage was scheduled in October to run a functional test on Diesel generator 4DG.

TRILLO PLANT

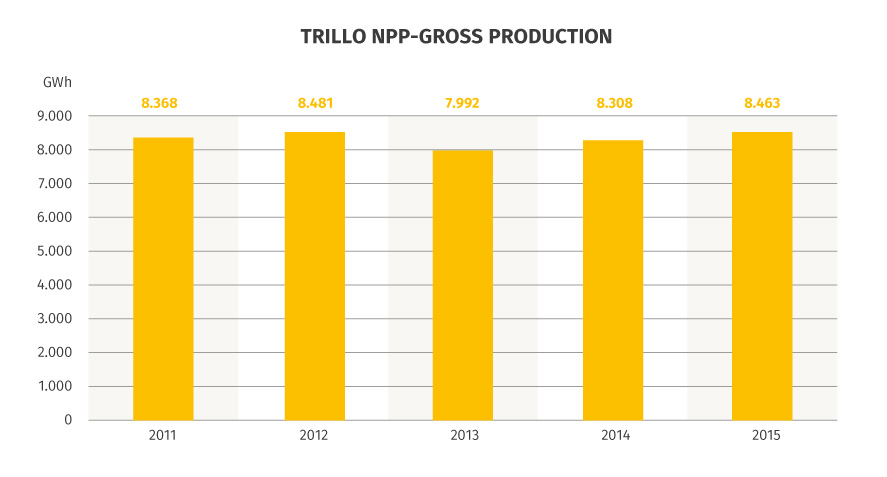

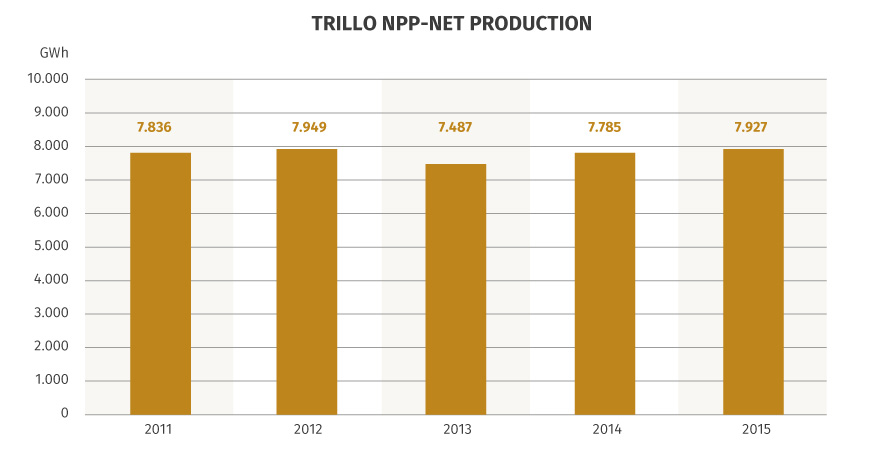

During 2015, gross production of electrical energy generated by the Trillo nuclear power plant was 8,463,389 MWh, and net production was 7,926,991 MWh. The Plant continues without experiencing any automatic reactor shut-downs for the eighth consecutive year. The twenty-seventh refuelling outage at Unit II lasted 31 days, from 29 April to 30 May.

Throughout the year we have worked on the construction of the new Emergency Management Standby Centre (EMSC), as established by the appropriate Nuclear Safety Council Technical Instruction, and almost 100% of the structural civil work and around 90 % of the mechanical, electrical and ventilation assembly phase were completed.

At 31 December 2015 the plant had 283.94 tons of nuclear material stored, held in over 30 dry storage containers.

ALMARAZ PLANT

The twenty-second refuelling and general maintenance of Unit II was carried out over 39 days in accordance with the overall programme planning, from 1 June to 11 July. The activities included work to replace 64 fuel elements, eddy current inspection of the steam generators, maintenance of both safeguards trains, inspection of the penetrations at the bottom of the reactor vessel, modifi cation of the "seal cones" of the reactor head, changing the NIS-44 chamber, including connectors and wiring, changing the pressurizer safety valves, replacing the motor of one of the reactor cooling pumps, inspection and electrical tests on the alternator and exciter, replacement of pipe sections and the tests corresponding to the fi rst refuelling of the fourth 10-year inspection interval.

Several improvements were implemented including some concerning redundant fi ltration at the fuel building, independence of electrical systems, transition to NFPA-805, continuous analysis of gases dissolved in transformers, fi ltration systems in buildings, and structural improvements in the safety equipment ventilation units.

This refuelling outage resulted in the execution of about 9,000 different activities and the incorporation of more than 1,200 workers in addition to the usual staffi ng complement, brought in from different partner companies to provide specialised services to the installation.

TRILLO PLANT

The twenty-seventh refuelling outage at Unit II took place between 29 April and 30 May. T he services of over forty specialised companies were employed for 31 days, providing around a thousand more individuals in addition to the usual staffi ng levels.

The refuelling and general maintenance activities included inspection of fuel elements and control rods and the reorganisation of fi ttings, electrical and mechanical inspection of redundancies 2 and 6, battery capacity tests in redundancies 3 and 7, and inspection of the components included in the pump and valve manuals. In addition, the turbinebypass control and protection system was modernised, and the seals, and upper and lower bearings in YD20D001 were inspected.

5,671 work orders were executed of which 2,956 were for corrective maintenance (52.1% of the total) and the remaining 2,715 for preventive maintenance (representing 47.9%).

During 2015 the installations operated completely normally, without producing any signifi cant incident that affected nuclear safety or radiological protection, the employees, or the plant environment.

The results obtained from the measurements performed show the dose rate for professionally exposed personnel was once again well below legal limits. In the case of Almaraz, the staff collective dose totalled 572.48 mSv per person for the combination of the two units, and at the Trillo Plant, the dose totalled 259.75 mSv per person.

As in recent years, CNAT has continued to make signifi cant investments aimed at improving the safety of its installations, and in the technological upgrading of its components and systems, so improving their reliability.

Based on the Operating Permit, both units at Almaraz Nuclear Power Plant have been equipped with a new redundant fi ltration system for the ventilation of each fuel building, in accordance with the requirements of RG 1.52, and the other fi ltration units in the remaining plant buildings have been adapted to RG 1.140. Fire protection improvements arising from compliance with NFPA 805 have also been completed together with improvements necessary to adapt the plant to RG 1.75 requirements.

As part of the technological renewal plan the design has been completed and the manufacture started of the new safety class units for cooling the Control Room and the 6.3 kV switch unit rooms, and replacement of the remaining cooling equipment by alternatives with gas which does not impact the ozone layer has been completed. Refurbishment of the main pumps motors has also been completed, and refurbishment of the start-up transformers has begun, together with the plan to renovate the 6.3 kV motors as well as the installation of new seal cones.

As part of the plans to modernise the instrumentation and control equipment, Trillo Nuclear Power Plant has successfully implemented the new turbine control and protection system and is progressing the design and manufacture of the new neumobolas system and the new level probes for the vessel, projects which will be implemented in 2016 and 2017.

One of the auxiliary transformers has been refurbished as part of the electrical renovation plans and the supply of new battery chargers and a new static converter has been instigated.

The IS30 project has also been implemented, and improvements in the reliability of the emergency and safeguards Diesel. As at Almaraz NPP, the cooling equipment is being replaced by alternative equipment which uses gas which does not impact the ozone layer.

As a result of analyses following the Fukushima accident, both the Almaraz and Trillo Nuclear Power Plants are constructing a new seismic building as an Emergency Management Support Centre (EMSC) and the implementation of a new wireless communications and lighting system has been completed to improve performance in emergencies. Both Plants are also designing a new fi ltered venting system for containment, which will be located in a new seismic building next to the Containment building. Finally, new hydrogen catalytic recombiners have been installed at Almaraz Nuclear Power Plant Unit 1, and this will be completed in 2016 with the installation in Unit 2. Trillo NPP already has this equipment.

Finally, a project has been instigated to build an Individual Temporary Storage (ITS) unit, which will house containers of spent fuel elements from 2018.

Quality is intrinsic to all activities at CNAT and is the main source of confi dence for our owners, the social environment, employees and business partners. Since 1995, CNAT's commitment to quality has been recognised by the Spanish Association for Standardisation (AENOR) which has granted an offi cial certifi cate, certifying the compliance of our Quality Management System with the UNE EN ISO 9001 standard for the production of electricity from nuclear sources. In 2015 AENOR carried out a follow-up audit to maintain certifi cation of our Quality System and found it to be satisfactory.

Voluntary international evaluations were also requested to determine the degree of excellence of the organisation. These included the WANO Corporate Peer Review, an independent evaluation by a group of international experts, which during December 2015 was conducted at the three CNAT work centres and the overall result was satisfactory. There were also the WANO Technical Support Mission (TSM) and INPO Technical Exchange Visits (TEV), which evaluate specifi c aspects with reference to best practices in the industry, and in 2015 there was the Almaraz Field Presence TSM, the Trillo Decision Making TSM and the Systems Engineering TEV.

Continuous Improvement is part of CNAT's organisational culture and that is why we manage improvement and studies, whose origin is not only independent internal evaluations (Quality Assurance audits and inspections), but also self-assessment by the units themselves of their activities and processes. In addition, trend analyses of low level incidents were conducted to enable identifi cation of preventive actions to avoid incidents of greater severity.