ACTIVITY REPORT

Refuelling has taken place at the two units during the year. On 25 January the twenty-first refuelling outage at Unit II took place, and between 23 June and 20 August the twenty-third refuelling outage at Unit I, and the work programme was successfully completed in 58 days resulting in zero accidents.

Besides the refuelling outages, there was a proactive but unscheduled outage at Unit II on 29 January, to replace the exciter and at Unit I, there was an automatic reactor shutdown on 17 September due to activation of the reactor protection system for low pressure in the pressurizer.

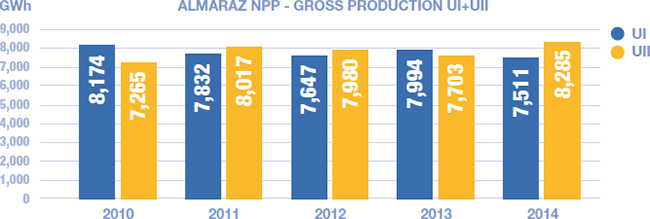

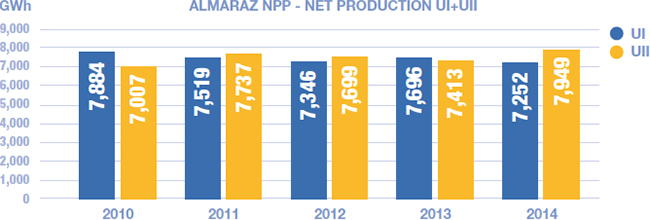

The gross output generated by the two Units at Almaraz Nuclear Power Plant was 15,795 million kWh, and the net joint production was 15,201 million kWh. Individually, gross electricity production by Unit I was 7,510.8 million kWh, and 8,284.5 million kWh by Unit II.

Gross electricity production accumulated at Almaraz since 1 May 1981 was 462,881,9 million kWh (233,513,3 by UI and 229,368,6 by UII).

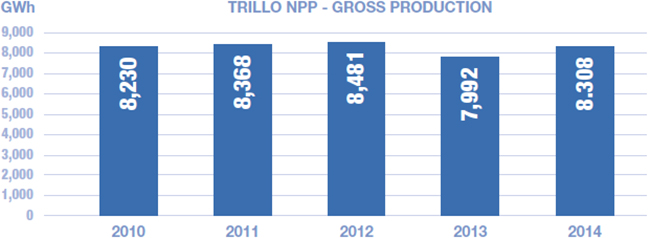

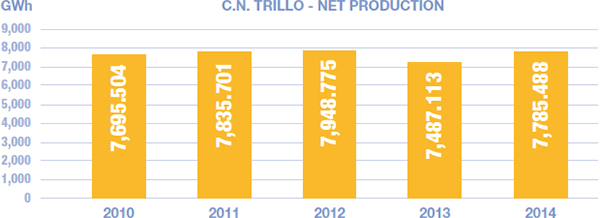

During 2014 Trillo Nuclear Power Plant achieved a successful annual operating balance, recording 8,308 GWh gross electricity and 7,785 GWh net electricity. There have been no automatic reactor shutdowns for 7 consecutive years. The twenty-sixth refuelling outage took 36 days from 23 May to 28 June.

The most notable event of the year was the renewal of the operating permit, valid for ten years from 17 November 2014, which the Ministry of Industry and Tourism granted to the Centrales Nucleares Almaraz-Trillo (CNAT) Economic Interest Grouping (Agrupación de Interés Económico).

Trillo Nuclear Power Plant has an accumulated gross electricity production from 14 May 1988 to 31 December 2014, of 213,478,000 kWh.

There were 28 containers with a total of 588 fuel elements in Individual Temporary Storage (ITS) on 31 December 2014.

The twenty-third refuelling and general maintenance of Unit II took place during the second half of 2014, from 23 June to 20 August. The general programme was executed as planned in 58 days and resulted in zero accidents.

During this period, more than 1,400 people in addition to the core workforce were recruited to the Plant to assist in the execution of about 9,000 refuelling activities, including the replacement of 64 fuel elements, performing preventive maintenance tasks and implementing various design modifications, notably those associated with implementation projects for the Alternative Shutdown Panel - ASP, increasing the seismic margin of equipment, adopting to the new fire protection rules (NFPA) and other Fukushimarelated improvements, such as implementing an electric generator and instrumentation for events beyond the design bases.

These design modifications were implemented before the twenty-first refuelling and general maintenance of Unit II which took place between 23 November 2013 and 25 January 2014. The collaboration of over 70 specialised service companies employing about 1,200 individuals were involved, in addition to the usual core workforce during these 63 days

The twenty-sixth refuelling and general maintenance outage took place between 23 May and 28 June 2014. The activity schedule was completed in 36 days and involved the services of over forty specialist firms which hired a thousand workers additional to the usual core workforce.

Notable activities carried out in addition to the replenishment of fuel, included inspection of the seals of the three main pumps of the primary pressurised water circuit, and inspection of the lower and axial bearings of the three main pumps; reviewing components of low pressure casing no. 2 of the turbine and changing the vane crown; inspection of redundancies; inspection of Loop no. 10 of the secondary steam circuit; inspection and cleaning of the steam generators, and various design modifications resulting from analysis of the stress tests.

During 2014 the installations operated completely normally, without producing any significant incident that affected nuclear safety or radiological protection, employees, or the plant environment.

The results obtained from the measurements show that the dose rate of professionally exposed personnel was again far below the legal limits established. In the case of Almaraz, the collective dose of staff totalled 554.82 mSv per person for the combination of the two units, and at the Trillo Plant, the dose totalled 297 mSv per person.

As has become the case in recent years, CNAT has continued to make a significant effort aimed at improving the safety of its facilities as well as technologically upgrading components and systems to improve their reliability.

At the Almaraz Nuclear Power Plant, and as a result of the operating permit awarded to Unit I for a new alternative shutdown panel (it was implemented in 2013 at UII), improvements in-hand also include a new room on the roof of the fuel building for installation of the new redundant filtration unit, fire protection improvements arising from compliance with NFPA 805, and improvements to cabinets and electrical conduits for adaptation to RG 1.75.

As part of the technological renewal plan the new safety class units have been allocated for cooling the Control Room and the 6.3 kV breaker rooms, and the design, manufacture and factory testing of the new Digital control system for auxiliary feedwater turbo has been completed and will be deployed at the next refuelling.

In the Trillo Nuclear Power Plant, and as part of the instrumentation and control equipment renewal plans, there are plans to implement the new turbine control and protection system during the next refuelling in May 2015. Preparation for the design of the new neumobolas system was started in 2014, as well as new vessel level probes, and these projects will be implemented in 2016 and 2017.

As a result of analyses following the Fukushima accident, both the Almaraz and Trillo Nuclear Power Plants, have been equipped with portable equipment and connections with the plant necessary to implement mitigation strategies for accidents beyond the design bases.

In addition, construction is underway at both plants for a new seismic building as an alternative emergency management centre, and deployment in 2015 of a new wireless communications and lighting system for better performance in emergencies. Finally the new containment filtered venting system is being developed for both Plants, and this will be located in a new seismic building close to the Containment building, where new catalytic hydrogen recombiners are being installed at Almaraz NPP (2016). Trillo NPP already has this equipment.

Quality is intrinsic to all activities at CNAT and is the main source of confidence for our owners, the social environment, employees and business partners. The commitment to quality at CNAT has been recognised by the Spanish Association for Standardisation and Certification (Asociación Española de Normalización y Certificación - AENOR) by the award since 1995, of an official certificate attesting compliance of our Quality Management System with the UNE EN ISO 9001 standard for nuclear originated power since 1995. In 2014, AENOR conducted a successful follow-up audit to maintain certification of our Quality System.

We also voluntarily submit to international assessments to determine the degree of organisational excellence. These include WANO Peer Reviews, which in December 2014 took place at Almaraz NPP with a satisfactory overall result; and WANO Technical Support Missions, to evaluate specific aspects with reference to best practices in the industry, and in 2014 they covered Trend Analyses and Self-Assessments.

Continuous Improvement is part of CNAT’s organisational culture and it is for this reason that we manage around 7,000 corrective and improvement actions, revisions and studies each year, based on internal and independent evaluation (Quality Assurance audits and inspections), and the units themselves conduct activity and process self-assessments. Furthermore, trend analyses of low level incidents are carried out to enable preventive actions to avoid the most significant incidents.